Executive Summary and Introduction

For the discerning homeowner in Central Florida, the selection of flooring is far more than a decorative choice; it is a foundational investment that dictates the longevity, value, and daily maintenance requirements of the home. Among the myriad options available—from luxury vinyl plank to porcelain tile—solid hardwood remains the aspirational standard. It offers a warmth, acoustic profile, and tactile luxury that synthetic materials struggle to emulate. However, the unique environmental conditions of the Florida peninsula, characterized by extreme humidity and prevalent slab-on-grade construction, position solid hardwood as a material of significant risk.

The question “Is solid hardwood a risk in Central Florida?” yields a complex answer. It is not strictly impossible, but it is technically demanding. The risk profile is substantially higher than in other regions of the United States. A successful installation requires a confluence of correct species selection, rigorous acclimatization protocols, specialized subfloor preparation, and unwavering climate control. Without these, the investment is prone to catastrophic failures such as cupping, crowning, and buckling.

This comprehensive research report serves as a definitive guide for homeowners in Tampa, Orlando, Sarasota, and surrounding areas. We will deconstruct the “Florida Flooring Myth,” analyze the biological interaction between diverse wood species and subtropical moisture, and provide a transparent, data-driven analysis of the costs associated with mitigating these risks. By integrating insights from the National Wood Flooring Association (NWFA), local market pricing data for 2025/2026, and forensic construction analysis, this report aims to build trust through transparency, helping you navigate the complexities of hardwood floor installation and make an educated decision for your home.

The Florida Flooring Paradox

The central paradox facing Florida homeowners is the desire for a natural, organic material in an environment that is hostile to organic stability. Wood is hygroscopic; it breathes. In the forests of the Appalachian Mountains or the Northeast, this is natural. In a sealed, air-conditioned home sitting on a damp concrete slab in 90% humidity, it is a mechanical liability.

Many homeowners are drawn to the aesthetic of solid wood, referencing historic Florida homes that have featured heart pine or oak for a century. However, modern construction methods have changed the equation. Historic homes were often built on pier-and-beam foundations, allowing air to circulate beneath the floor. Modern homes in communities like Lake Nona, Winter Park, and Wesley Chapel are predominantly built on concrete slabs. This fundamental shift in engineering requires a completely different approach to flooring.

To understand why solid hardwood is risky, we must first understand the invisible forces at play: the moisture vapor transmission from the ground up, and the relative humidity fluctuations from the air down.

1: The Science of Hygroscopy and Environmental Stress

Wood is not an inert building material like steel or plastic; it is a cellular structure composed of cellulose, hemicellulose, and lignin. Even after it is felled, milled, and finished, wood remains biologically reactive to its environment. This reactivity is defined by hygroscopy—the ability of a substance to attract and hold water molecules from the surrounding environment.

1.1 The Mechanism of Movement

In a living tree, the cellular structure is designed to transport water. In a floorboard, these same cells act as sponges. When the relative humidity (RH) of the air rises, the cell walls absorb moisture and swell. When the RH drops, they release moisture and shrink.

This movement is not uniform. Wood is anisotropic, meaning it moves differently in different directions:

- Tangential Movement: This occurs across the width of the board and is the primary source of flooring failures. A 5-inch wide plank can expand significantly during a humid summer.

- Radial Movement: This occurs perpendicular to the growth rings and is generally more stable.

- Longitudinal Movement: This occurs along the length of the board and is usually negligible.

In Central Florida, where outdoor humidity can fluctuate from 50% to 100% within a 24-hour period, the vapor pressure differential between the outdoors and the air-conditioned indoors is extreme. If the home’s building envelope is not perfectly sealed, or if the HVAC system is not effectively removing latent heat (moisture), the wood flooring becomes the buffer, absorbing the excess water vapor.

1.2 Equilibrium Moisture Content (EMC)

The Holy Grail of hardwood stability is Equilibrium Moisture Content (EMC). This is the state where the wood is neither gaining nor losing moisture from the air. In most of North America, an EMC of 6% to 9% is standard. In Florida, due to higher average humidity, the EMC is often higher.

If a solid oak floor is installed at 6% moisture content (common for factory-dried wood) into a Florida home where the ambient environment dictates an EMC of 11%, the wood will expand as it absorbs moisture to bridge that 5% gap. This expansion manifests as physical force. The wood will push against walls, cabinets, and adjacent boards. If expansion gaps are insufficient, the floor has nowhere to go but up (buckling).

1.3 The Three Horsemen of Flooring Failure

When hygroscopic forces overwhelm the installation, three primary types of damage occur. Recognizing these is essential for any homeowner evaluating the condition of their current floors or the risks of a new installation.

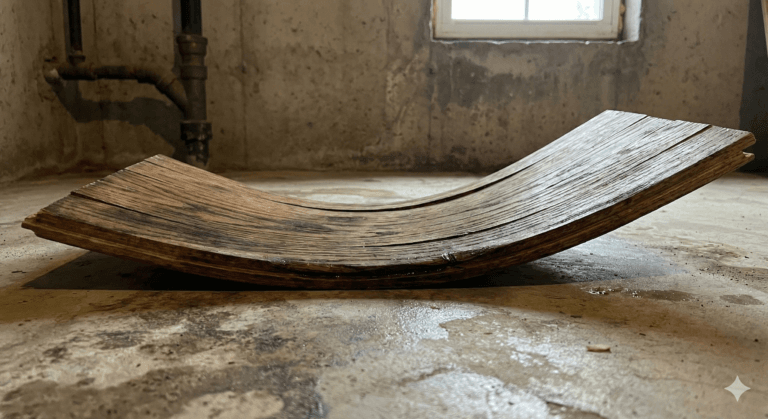

Cupping

Cupping is the most prevalent issue in Florida. It is characterized by the edges of the board rising higher than the center, creating a concave shape across the width of the plank.

- The Cause: Cupping almost always indicates a moisture imbalance where the bottom of the board is wetter than the top. In Florida, this is the hallmark of moisture migrating up from the concrete slab through an inadequate vapor barrier. The bottom of the plank swells while the top (exposed to dry AC air) remains stable, curling the edges upward.

- The Implication: If you see cupping, you have a subfloor moisture problem, not just a humidity problem.

Crowning

Crowning is the inverse of cupping: the center of the board is higher than the edges.

- The Cause: This can occur if the surface of the floor is exposed to standing water (like a leak). However, in renovation contexts, it is often a sign of an impatient repair. If a floor cups and is sanded flat before it has dried out, the edges are shaved down. When the wood eventually dries and relaxes, the edges sink, leaving the center permanently raised.

Buckling

This is the most catastrophic failure. The wood expands so forcefully that it detaches from the subfloor, lifting inches into the air.

- The Cause: This is typically the result of flooding or a complete lack of expansion gaps around the perimeter. In Florida, this can happen after hurricanes or extended power outages where AC is lost for days.

2: The Concrete Foundation Challenge

The geology and construction standards of Central Florida present a unique adversary to solid hardwood: the concrete slab-on-grade. Unlike homes in the Northeast with basements or crawlspaces, Florida homes typically sit directly on the earth.

2.1 The Concrete Sponge

Concrete appears solid, but on a microscopic level, it is a rigid sponge. It is porous and subject to capillary action, where moisture from the ground is wicked up through the slab to the surface.

- The Vapor Drive: Even if a slab looks dry, it is constantly emitting water vapor. In Florida, the high water table increases the hydrostatic pressure, pushing more moisture through the concrete.

- The Conflict: Solid hardwood is organic. Concrete is wet and alkaline. Placing solid wood directly on concrete is a violation of building physics. The moisture from the concrete will rot the wood or cause severe expansion.

2.2 The Subfloor Requirement (and the Cost of Height)

Because solid hardwood cannot be glued directly to concrete (the moisture risk is too high and solid wood needs to move), a wooden subfloor must be constructed on top of the slab. This is a critical “hidden” factor in both cost and logistics.

The NWFA Compliant Assembly for Florida:

- Vapor Retarder: A 6-mil polyethylene sheet or liquid membrane applied to the concrete.

- Plywood Subfloor: Sheets of ¾-inch plywood are fastened to the slab. This provides a nailable surface for the hardwood.

- Moisture Paper: A layer of asphalt-saturated felt is placed between the plywood and the hardwood.

- Solid Hardwood: The planks are nailed into the plywood.

The Logistics of Vertical Height:

Adding ¾-inch plywood plus ¾-inch hardwood raises the floor height by 1.5 inches. This creates significant issues:

- Doors: All interior doors must be trimmed.

- Appliances: Dishwashers may be trapped under countertops.

- Transitions: Significant trip hazards or steep ramps are created where the wood meets tile or carpet in other rooms.

This structural complexity is a primary reason why flooring contractors often steer Florida homeowners away from solid wood. It is not just about the wood; it is about the geometry of the house.

3: Solid vs. Engineered Hardwood – A Deep Comparative Analysis

The flooring industry has responded to the challenges of concrete and humidity with the development of engineered hardwood. For the Central Florida homeowner, understanding the technical distinction between “solid” and “engineered” is the difference between a high-maintenance liability and a high-performance asset.

3.1 Solid Hardwood: The Traditionalist’s Liability?

Solid hardwood is milled from a single piece of timber. Its grain runs in one direction.

- Pros: It can be sanded and refinished many times (4-7 times), offering a lifespan of 100+ years. It is the “purest” form of flooring.

- Cons in Florida: Because the grain is unidirectional, it has no internal resistance to warping. If it wants to twist, it twists. It is “wild” wood.

- Verdict: In Florida, solid hardwood is a luxury item that requires a controlled environment. It is akin to owning a classic car; it requires constant care and garage storage (climate control).

3.2 Engineered Hardwood: The Structural Solution

Engineered hardwood is real wood. The top layer (lamella) is the exact same oak, maple, or walnut as a solid plank. However, the core underneath is constructed of high-quality plywood or HDF with grains running perpendicular to each other.

The Cross-Ply Technology:

This cross-grain construction is the key. When humidity rises, the top layer tries to expand widthwise. However, the layer underneath it runs lengthwise and physically restricts that movement. This opposing force creates a “dimensionally stable” plank.

- Stability Factor: Engineered wood is up to 700% more stable than solid wood. It can withstand the humidity swings of a Florida summer without cupping.

- Installation Advantage: Because it is stable, it can be glued directly to the concrete slab (using a moisture-barrier adhesive), eliminating the need for a plywood subfloor. This saves vertical height and thousands of dollars in subfloor labor.

- Wear Layer Concerns: The only downside is the wear layer. A cheap engineered floor may have a 1mm veneer that cannot be sanded. A high-quality engineered floor will have a 4mm-6mm wear layer, allowing for 3-5 refinishings—nearly matching solid wood’s lifespan.

Table 1: Solid vs. Engineered Hardwood Comparison for Florida

| Feature | Solid Hardwood | Engineered Hardwood |

| Composition | 100% Solid Wood (Single Piece) | Real Wood Veneer over Plywood Core |

| Humidity Tolerance | Low (Highly reactive to moisture) | High (Dimensionally stable construction) |

| Primary Failure Risk | Cupping, Buckling, Gapping | Delamination (rare in quality products) |

| Installation Method | Nail-down over Plywood Subfloor | Glue-down direct to Concrete or Float |

| Floor Height Impact | Adds ~1.5 inches (Plywood + Wood) | Adds ~0.5 – 0.75 inches (Low profile) |

| Refinishing Potential | Excellent (4-7 times) | Good (1-4 times depending on wear layer) |

| Suitability for Florida | Risky (Requires strict climate control) | Recommended (Best for slabs & humidity) |

Data synthesized from NWFA guidelines and manufacturer specifications.

4: Wood Species Selection – The “Do Not Buy” List

If you decide to proceed with wood flooring (solid or engineered), the species you select is the next critical variable. The cellular structure of different trees handles moisture differently. In Florida, we look for two metrics: Hardness (Janka Scale) and Stability (Coefficient of Change).

4.1 The “Avoid at All Costs” List

Some woods are biologically incompatible with the Florida climate due to high reactivity.

- American Beech: This is arguably the worst choice for a humid climate. Beech has a very high shrinkage coefficient and is exceptionally sensitive to moisture. It will move, cup, and rot faster than almost any other hardwood in Florida conditions. Snippets explicitly warn that Beech absorbs water quickly, is prone to decay, and should not be used in humid zones.

- Maple: While hard (Janka 1450), Maple is dense and light-colored. Its tight grain makes any gaps that form very visible. It is known as a “nervous” wood that reacts quickly to humidity changes. In Florida, solid maple often develops unsightly gaps or minor cupping that disrupts its smooth, glass-like aesthetic.

- Birch: Similar to Maple and Beech, Birch is less stable than Oak and prone to rot if moisture barriers fail.

4.2 The “Florida Safe” List

These species have a track record of performance in subtropical climates.

- White Oak: The industry standard. White Oak is more water-resistant than Red Oak due to tyloses (cellular growths) that plug the pores of the wood. This is why White Oak is used for wine barrels and boat building. It is stable, takes stain well, and its grain hides minor movement.

- Teak: The gold standard for moisture resistance. Teak is oily and dense, naturally repelling water and rot. It is widely used in marine decking. While expensive, it is one of the safest bets for a Florida home.

- Ipe (Brazilian Walnut): An incredibly dense tropical hardwood. It is so hard it has a Class A fire rating and is virtually impervious to water, termites, and rot. However, it is difficult to install due to its density.

- Live Oak / Heart Pine: Native species. If you can source reclaimed Heart Pine, its high resin content makes it naturally resistant to the pests and humidity of the region it grew in.

5: Installation – The High Cost of Cutting Corners

The most common cause of flooring failure in Florida is not the wood itself, but the installation. The phrase “flooring installation near me” often leads to a mix of certified professionals and unlicensed handymen. In Florida, the difference is often catastrophic.

5.1 The Acclimation Myth

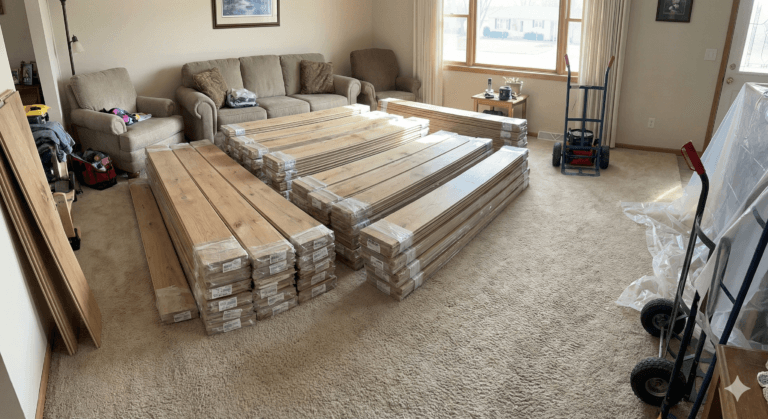

A pervasive myth is that wood just needs to sit in the garage or the living room for 48 hours before installation. This is false and dangerous.

- The Science: Acclimation is not about time; it is about moisture equilibrium. The wood must be within 2-4% moisture content of the subfloor before installation can begin.

- The Protocol: The HVAC must be running and the home must be at “living conditions” (approx. 75°F / 45-50% RH) for at least 5 days before the wood is delivered. The wood is then tested with a moisture meter. It might take 4 days or 4 weeks to reach equilibrium. Installing before this point guarantees gaps or buckling.

5.2 The Subfloor Prep and Vapor Barriers

For glue-down engineered floors (the most common Florida method), the concrete must be clean and, crucially, level.

- Flatness: The NWFA standard is 3/16″ flatness over a 10-foot radius. If the slab has dips, the glue will not bond the wood to the concrete, leading to “hollow spots” that pop and creak when walked on.

- Vapor Barrier Adhesive: Installers must use premium urethane adhesives that contain a vapor barrier. These glues act as a rubberized shield between the wet slab and the wood. Cheap glues will crystallize and fail, allowing moisture to cup the floor.

5.3 2025/2026 Price Research: The Cost of Doing It Right

Homeowners often underestimate the cost of flooring installation services in Florida because they fail to account for the necessary prep work. Below is a detailed estimated price range for materials and services in the Tampa/Orlando/Central Florida market for 2025/2026.

Table 2: Estimated Hardwood Flooring Costs in Central Florida (2025/2026)

| Cost Category | Item | Estimated Price Range (Per Sq. Ft.) | Notes |

| Materials | Engineered Hardwood (Mid-Range) | $5.00 – $10.00 | Oak, Hickory (Safe choices) |

| Engineered Hardwood (Premium) | $10.00 – $16.00 | Wide plank, thick wear layer | |

| Solid Hardwood (Material Only) | $6.00 – $12.00 | Requires plywood subfloor | |

| Luxury Vinyl Plank (Alternative) | $3.50 – $7.00 | 100% Waterproof | |

| Installation | Glue-Down Installation (Labor) | $3.00 – $5.00 | Standard for engineered on slab |

| Nail-Down Installation (Labor) | $3.50 – $6.50 | For solid wood (excludes subfloor cost) | |

| Plywood Subfloor Install | $4.50 – $10.00 | REQUIRED for solid wood on slab | |

| Preparation | Old Tile Removal | $2.75 – $5.00 | Includes disposal |

| Carpet Removal | $0.75 – $1.60 | Includes disposal | |

| Concrete Leveling | $1.00 – $4.00 | Critical for hollow-spot prevention | |

| Moisture Barrier Adhesive | $1.00 – $2.00 | Essential for warranty |

The Hidden “Solid Wood Tax”:

A homeowner choosing Solid Hardwood for a 1,000 sq. ft. living area on a slab should expect to pay an additional $4,500 to $10,000 just for the installation of the plywood subfloor required to make the solid wood work. This makes solid hardwood significantly more expensive than engineered hardwood or tile alternatives.

6: Living with Hardwood – Maintenance and Care

Once the floor is installed, the burden of performance shifts to the homeowner. Maintaining hardwood in Florida requires vigilance.

6.1 Climate Control is Mandatory

The warranty on your floor is likely void if the indoor relative humidity falls outside the 35% – 55% range.

- Dehumidifiers: In the “shoulder seasons” (Spring/Fall) when the AC runs less frequently, humidity can spike indoors. A whole-home dehumidifier or portable units are often necessary to keep the wood stable.

- Vacation Settings: “Snowbirds” or those leaving for vacation cannot simply turn the AC off. The home must remain conditioned. If the temperature rises to 85°F and humidity hits 80%, the floor will likely buckle.

6.2 Cleaning Protocols

- No Wet Mops: Never use a wet mop or steam mop. Water and wood are enemies. Use a microfiber dust mop for daily cleaning.

- Specialized Cleaners: Use pH-neutral cleaners specifically designed for polyurethane finishes (e.g., Bona). Avoid oil soaps or waxes, which leave residues that make future refinishing impossible.

- Sand and Salt: Central Florida soil is sandy. Sand acts like 60-grit sandpaper on a wood floor. Mats at every entrance and a “no shoes” policy are the best defenses against scratching.

6.3 UV Protection

Florida is the Sunshine State. UV radiation will oxidize wood, causing light woods to yellow (ambering) and dark woods to fade (bleaching).

- Strategy: Install Low-E windows or UV-blocking window film. Rotate area rugs and furniture every few months to ensure the floor color changes evenly rather than leaving “shadows” where rugs sat.

Conclusion: Is the Risk Worth the Reward?

Is solid hardwood a risk in Central Florida? Yes. It is a material that fights against the very physics of the Floridian environment. The combination of high humidity and concrete slab foundations creates a hostile ecosystem for solid planks. The requirement for complex subfloor systems adds significant cost and vertical height issues that many homeowners find prohibitive.

However, the risk is manageable for those who are:

- Educated: Understanding that acclimation and moisture testing are non-negotiable.

- Budgeted: Willing to pay for the proper plywood subfloor and moisture mitigation systems.

- Disciplined: Committed to maintaining indoor humidity levels year-round, even when away.

The Strategic Recommendation:

For the vast majority of Central Florida homeowners, Engineered Hardwood is the superior engineering solution. It delivers the aesthetic beauty, value, and tactile experience of real wood (because it is real wood) while neutralizing the structural risks associated with humidity and concrete. It allows for wider planks, easier installation, and lower costs, all while providing a floor that is likely to outlast a solid floor that has succumbed to cupping or buckling.

If you are searching for “flooring installation near me,” prioritize contractors who speak fluent “moisture mitigation.” Ask about their acclimation process, their moisture testing equipment, and their experience with engineered vs. solid products on slabs. Your floor is the foundation of your home’s design; ensure it is built on a foundation of science and trust.

Final Checklist for the Homeowner

- [ ] Test the Slab: Has a calcium chloride or RH probe test been done?

- [ ] Choose Stability: Have you considered White Oak or Teak over Beech or Maple?

- [ ] Acclimate Correctly: Is the HVAC on? Is the wood being tested with a meter?

- [ ] Check the Glue: Is a urethane moisture-barrier adhesive being used?

- [ ] Verify the Gap: Are there expansion gaps at all walls?

By adhering to these principles, you can navigate the risks and enjoy the timeless beauty of wood flooring in the heart of Florida.