The Florida Flooring Paradox

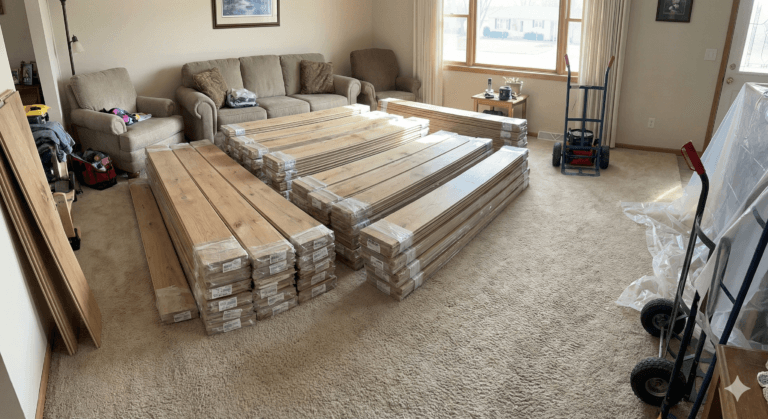

The search for the perfect floor in the state of Florida differs fundamentally from any other region in North America. Homeowners in the “Sunshine State” face a unique paradox: they desire the aesthetic warmth, organic texture, and visual elegance of natural wood, but they inhabit an environment that is aggressively hostile to organic materials. The combination of subtropical humidity, air laden with coastal salinity, intense exposure to ultraviolet rays, and the ubiquity of slab-on-grade concrete foundations creates a “perfect storm” capable of degrading traditional flooring materials at an alarming rate.

For decades, the flooring industry has attempted to bridge this gap between aesthetic desire and environmental reality. Two contenders have emerged as leaders in this competitive landscape: Luxury Vinyl Plank (LVP) and Laminate Flooring. Both promise the visual appeal of wood or stone at a fraction of the cost, and both claim durability that surpasses the natural materials they mimic. However, marketing language often obscures the technical realities that determine longevity in a humid climate.

This report serves as a comprehensive and deep analysis, designed specifically for the Central Florida homeowner. It goes beyond surface-level comparisons to explore molecular composition, structural integrity, and economic implications of choosing between LVP and Laminate. By dissecting the “Battle of Humidity”—from vapor emissions in concrete slabs to the swelling rates of wood fiber cores—this document aims to provide the definitive decision-making framework to build confidence and ensure long-term satisfaction in Florida homes.

1: The Contenders – Defining Technology and Molecular Composition

To truly understand how these floors perform under the stress of the Florida climate, we must first deconstruct what they are. The difference between success and catastrophic failure often lies in the microscopic composition of the plank’s core. It is not just “plastic versus wood,” but complex composite engineering.

1.1 Luxury Vinyl Plank (LVP): The Evolution of Resilient Flooring

Luxury Vinyl Plank (LVP) has undergone a radical transformation in the last decade. It is no longer the flexible, peel-and-stick, low-quality vinyl of the past. Modern LVP is a sophisticated composite material, engineered for dimensional stability and total impermeability.

The Core Technologies: The Difference Between SPC and WPC

The term “Luxury” in LVP refers primarily to the rigid core technology that gives the plank its structure and “body,” distinguishing it from traditional vinyl sheets. There are two primary variations relevant to the Florida market, and the distinction between them is crucial for longevity:

- SPC (Stone Plastic Composite): This is the current “gold standard” for Florida slabs. The core is composed of limestone powder (calcium carbonate), polyvinyl chloride (PVC), and stabilizers.

- Technical Insight: The limestone content makes the core incredibly dense and rigid. It acts as a thermal anchor, resisting expansion and contraction caused by temperature fluctuations—a critical feature for homes with large sliding glass doors exposed to the scorching Florida sun. Unlike organic materials that “breathe,” SPC is inert.

- Moisture Profile: Being a fusion of stone and polymer, SPC cores are hydrophobic. They possess no porosity to absorb water. This makes them chemically inert to moisture rising from concrete slabs, preventing swelling or structural warping.

- WPC (Wood Plastic Composite): Often marketed as a “waterproof core,” this material blends wood flour or wood-like dust with plastic agents and foaming agents.

- Technical Insight: Foaming agents create microscopic air pockets, making WPC softer, warmer, and quieter underfoot compared to the denser SPC. However, the inclusion of “wood” elements and air, even when encapsulated in plastic, introduces a minor variable regarding thermal expansion. While still waterproof in terms of integrity, it is generally less dimensionally stable than SPC in extreme heat windows, which can lead to locking mechanism failures in enclosed lanais or areas with direct sunlight.

The Wear Layer

Superior durability is determined by the wear layer, a transparent vinyl coating applied over the high-definition photographic print.

- Measurement: It is measured in “mils” (thousandths of an inch), not millimeters. This is a vital distinction that confuses many consumers.

- Market Standard: A 12-mil layer is standard for light residential use, while 20 to 22-mil layers are recommended for homes with pets (large dogs) or heavy traffic.

- Reinforcement Chemistry: Most high-quality LVP wear layers are reinforced with ceramic beads or aluminum oxide suspended in the urethane resin to resist abrasion from sand and debris, acting as a microscopic shield.

1.2 Laminate Flooring: The Wood-Based Alternative

Laminate flooring is the veteran in this battle, introduced decades ago as a cheaper and easier-to-install alternative to solid hardwood. It is a multi-layer synthetic flooring product fused together through a lamination process.

Composition and Vulnerability

- The Core (HDF): The heart of a laminate plank is High-Density Fiberboard (HDF). This is composed of wood fibers (cellulose) that have been broken down, mixed with resin and wax, and compressed under extreme heat and pressure.

- Technical Weakness: Despite the resin, the core is fundamentally cellulose—a material that behaves like a sponge. It is hygroscopic, meaning it naturally seeks to absorb moisture from the atmosphere to reach equilibrium with its environment. In Florida, where relative humidity is high, HDF is in a constant state of tension, attempting to absorb water.

- The Surface: The top layer is a melamine resin reinforced with aluminum oxide. This layer is exceptionally hard—often harder than the vinyl wear layer of LVP—making it highly resistant to surface scratches. However, it is brittle and does not protect cut edges or locking joints in the same way.

The “Waterproof” Laminate Confusion

In recent years, manufacturers have introduced “waterproof” or “water-resistant” laminate to compete with LVP. It is crucial to analyze this marketing claim with scientific rigor.

- Mechanism: These products generally use a hydrophobic sealant on the click mechanism and a chemically treated, denser HDF core to repel water for a specific duration (e.g., 24, 72, or 80 hours).

- Reality Check: While these innovations have improved performance, they do not alter the fundamental physics of the material. If the barrier is breached—through a deep scratch, a poorly fitted joint, or prolonged submersion—the wood fibers will eventually swell. Once HDF swells, it does not shrink back to its original shape upon drying; the deformation is permanent, creating irreversible peaking at the joints.

2: Central Florida Climate Analysis

The central thesis of this report is that geography dictates flooring choice. Central Florida—encompassing Tampa, Orlando, Gibsonton, and coastal regions—presents a specific set of environmental stressors that are rare in other parts of the country. Understanding these stressors is fundamental to avoiding premature flooring failure.

2.1 The Concrete Sponge: Slab Moisture and Hydrostatic Pressure

In Florida, basements are virtually nonexistent due to the high water table. Homes are built on slab-on-grade concrete foundations. While concrete appears solid and impenetrable, it is actually porous, effectively functioning as a hard, dense sponge.

The Hidden Moisture Bomb

Florida has an extremely high water table. Soil moisture constantly migrates upward through the dirt and into the concrete slab, driven by capillary action and hydrostatic pressure.

- Vapor Emission (MVER): Even in a house that feels dry, the concrete slab is constantly emitting water vapor. In older Florida homes (pre-2000) that may lack an effective vapor barrier under the slab (visqueen), this emission rate can be significant.

- The “Sweating” Slab: When humid outdoor air (common in Florida summer) meets a concrete slab cooled by air conditioning, condensation can occur on the surface. If flooring is installed over this without proper prep, moisture gets trapped.

Comparative Impact: LVP vs. Laminate

- LVP Response: An SPC vinyl plank is impervious to this rising vapor. It effectively “caps” the moisture, preventing it from passing into the room. However, if moisture emission is extreme (above 4-5 lbs per 1,000 sq. ft.), vapor pressure can eventually compromise adhesives used in glue-down installations or cause mold growth under a floating floor, but the plank itself remains intact and dimensionally stable.

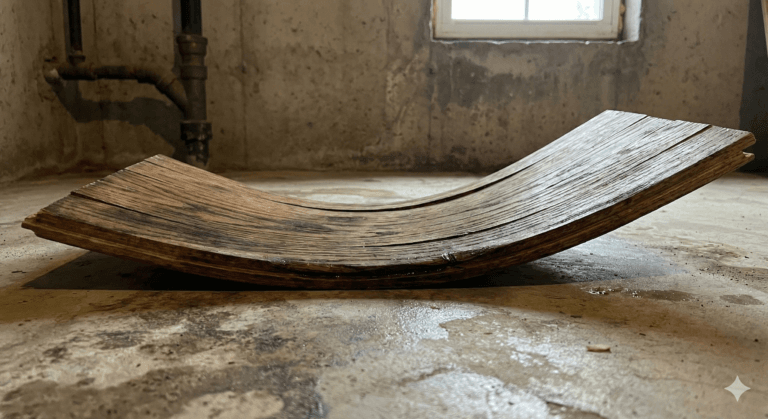

- Laminate Response: This is Laminate’s “Achilles’ Heel” in Florida. As vapor rises from the slab, the HDF core of the laminate absorbs it from the bottom up. This is insidious because the floor may look perfect on top, but the core is slowly expanding.

- Cupping: Because the bottom of the plank swells while the top remains dry (thanks to the melamine layer), the edges curl upward, creating a “cup” or canoe appearance.

- Mold Food: Organic wood fibers in laminate provide a food source for mold if moisture gets trapped between the slab and the floor, creating a hidden biohazard.

2.2 Ambient Humidity: The Air We Breathe

The average Relative Humidity (RH) in Central Florida hovers between 70% and 90% for much of the year. While AC dehumidifies interiors, opening doors and windows introduces massive spikes in indoor humidity.

- Laminate’s Hygroscopic Cycle: Laminate flooring is constantly “breathing.” In high humidity, it absorbs moisture and expands. When the AC dries the air, it shrinks. This constant dimensional movement stresses the click-lock mechanisms. Over time, this can lead to “gapping” at the seams or creaking noises.

- LVP Stability: LVP, particularly rigid core SPC, possesses a coefficient of expansion close to zero regarding moisture. It does not react to air humidity. This dimensional stability is why LVP can often be installed in large open-concept Florida homes (up to 4,000 sq. ft.) without the need for unsightly transition strips (T-moldings) that laminate floors require every 30-40 linear feet to accommodate expansion.

2.3 The Sandpaper Effect: Sand and Silica

Florida is a peninsula of sand. It enters the home on shoes, pet paws, and beach gear.

- Abrasion Analysis: Sand is composed of silica, which is harder than most floor finishes. It acts like 60-grit sandpaper underfoot.

- Laminate Technical Advantage: Here, laminate holds a slight technical edge. The aluminum oxide top coating of high-quality laminate (AC4 or AC5 rating) is incredibly hard and resists micro-scratches better than standard vinyl.

- LVP Vulnerability: Vinyl is inherently softer. Over time, sand can dull the finish of LVP, causing “micro-abrasion” that turns the wear layer cloudy.

- Mitigation: For LVP in Florida, it is critical to look for coatings infused with “Ceramic Bead” or “Diamond” technology, which significantly harden the wear layer against sand abrasion, leveling the playing field with laminate.

3: The Battle of Humidity – Water Resistance vs. Waterproofing

This distinction is the most critical for a Florida homeowner to grasp. Marketing terms often blur the lines, but material physics is distinct and unforgiving.

3.1 The Reality of the “Submersion Test”

To truly understand the difference, one must look at extreme stress tests which simulate real accidents.

- LVP Scenario: If you take a piece of SPC Luxury Vinyl Plank and submerge it in a bucket of pool water for a week, then remove it, it will be wet but structurally identical. It will not have swollen, warped, or delaminated. It will click back into place perfectly. It is Waterproof.

- Laminate Scenario: If you do the same with “Waterproof” Laminate, the result is different. Even high-quality waterproof laminates rely on edge sealants and surface tension. Once submerged, water pressure eventually bypasses the seal. The HDF core swells (rates vary from 8% to 15% expansion depending on quality). Upon drying, the fibers do not fully retract. The plank is ruined. It is Water-Resistant, not waterproof.

3.2 Real Florida Disasters

Flooring choice isn’t just about daily wear; it’s about survivability during common Florida incidents.

The AC Handler Failure / Dishwasher Leak

In Florida, air handler units are often located in indoor closets or garages. Condensate line clogs are common due to algae growth.

- Laminate: A slow leak that goes unnoticed for 48 hours (e.g., during a weekend away) can destroy a laminate floor in the hallway adjacent to the AC closet. Water penetrates the joints, causing seam lifting. The entire section usually requires replacement, and finding a matching dye lot years later is nearly impossible.

- LVP: The water sits on the surface (or goes underneath). You vacuum up the water with a wet-vac, pull up a few planks to let the concrete dry (to prevent mold), and reinstall the same planks. Zero material loss.

Hurricane Season & Flooding

While no floor withstands a catastrophic storm surge that washes the house away, minor flooding and water intrusion from wind-driven rain are realities.

- LVP Survival: After minor flood events (clean water or rain), LVP is often the only floating floor that can be salvaged. It can be uninstalled, sanitized with anti-mold products, dried, and reinstalled.

- Laminate Mortality: Any flood event involving standing water generally renders laminate an immediate total loss due to rapid core saturation. Homeowners insurance often covers replacement, but the renovation inconvenience is massive.

4: Durability and Lifestyle Considerations

Beyond water, how do these floors live with the home’s inhabitants?

4.1 Scratch Resistance vs. Impact Resistance

There is a physical trade-off between hardness and flexibility.

- King of Scratches (Laminate): The melamine surface is extremely hard. For homeowners with large dogs that have sharp nails and run through the house, highly-rated laminate (AC4) is less prone to showing white surface scratch marks than vinyl.

- King of Impact (SPC Vinyl): If you drop a heavy can of soup in the kitchen:

- Laminate: The hard, brittle surface may chip or crack, exposing the brown HDF core. Repair is difficult and usually requires visible filler putty.

- LVP: Vinyl possesses a degree of tensile flexibility (even with a stone core) and will absorb the shock. It may dent slightly, but rarely cracks or shatters. A dent is often less visible than a chip.

4.2 Sound and Comfort (Acoustics)

Florida homes often feature open floor plans, high ceilings, and many tile surfaces, creating natural echo chambers. Flooring plays a huge role in acoustic dampening.

- The “Hollow” Click: Laminate is notorious for the “hollow” clicking sound when walked upon with hard shoes or dog nails. This occurs due to the rigid HDF core vibrating against the subfloor. It demands a high-quality acoustic underlayment (cork or heavy rubber) to mitigate this, increasing the cost.

- The Quiet Step: WPC vinyl is the quietest due to its foamed core. SPC is louder than WPC but generally quieter and has a more “solid” sound (thud) than laminate. Many premium LVP products come with an attached IXPE (cross-linked polyethylene) acoustic pad that significantly dampens sound.

- Condo Alert: For Florida condos (especially 2nd floor and up), HOA rules strictly regulate sound transmission (IIC Ratings – Impact Insulation Class). LVP with attached acoustic padding is often the easiest way to meet strict IIC 50-55 requirements without buying expensive separate underlayment.

Part V: The Installation Battle – Where Costs Hide

Installation in Florida presents unique challenges, primarily due to the condition of concrete slabs.

5.1 Subfloor Preparation: The Hidden Florida Cost

Florida concrete slabs are rarely perfectly flat. They may have “waves” or dips.

- SPC Requirement: Rigid core LVP (SPC) demands an extremely flat subfloor. If there are dips, the click joints can break under pressure. This often necessitates the use of “self-leveling compound.”

- Laminate Tolerance: Laminate, being thicker and rigid in a different way, can sometimes “bridge” small imperfections better than thin vinyl, but still requires leveling to avoid the hollow sound and joint failure.

- The Cost Factor: Ignoring leveling is the number one cause of installation failure. Homeowners must budget for floor prep, not just plank installation.

5.2 Removing Old Flooring

Many Florida homes have old ceramic tile throughout the living area.

- Tile Removal: It is a dusty, noisy, and expensive job ($2.00 – $4.00 per sq. ft.).

- Floating Over: LVP (and laminate) can often be installed over existing tile, provided the tile is well-adhered and grout lines are not too deep (or are filled with patch). This saves thousands of dollars in demolition costs. SPC is particularly good at this due to its rigidity, which does not “telegraph” grout lines to the surface.

5: Price Survey – Central Florida Market 2025

For homeowners, the decision often comes down to the bottom line. We conducted a pricing analysis for the Tampa Bay / Orlando / Gibsonton market area for 2025, factoring in materials and local labor rates.

6.1 Cost Variables

- Material Quality: Prices vary widely, from “Big Box” store promotions to specialized flooring retailers.

- Entry Level: LVP with 12-mil wear layer or AC3 Laminate.

- Mid-Range: 20-mil SPC LVP or AC4 Water-Resistant Laminate.

- Premium: 22-30 mil Designer LVP with Embossed-in-Register (EIR) or AC5 Laminate.

- Labor: Labor rates in Central Florida have stabilized but remain high due to construction demand.

- Floating (Click-Lock): Cheaper installation.

- Glue-Down: More expensive (requires more adhesive and labor time, and a perfect slab).

6.2 Estimated Pricing Table (Central Florida 2025)

The following table estimates total installed cost per square foot (sq. ft.) for a standard renovation of a 500 sq. ft. living area.

| Cost Component | Economy LVP / Laminate | Mid-Range LVP (SPC) | Premium LVP / Waterproof Laminate |

|---|---|---|---|

| Material Cost | $2.00 – $3.50 / sq. ft. | $3.50 – $5.50 / sq. ft. | $6.00 – $9.00+ / sq. ft. |

| Basic Installation Labor | $1.50 – $2.50 / sq. ft. | $2.00 – $3.00 / sq. ft. | $2.50 – $4.00 / sq. ft. |

| Old Floor Removal (Carpet) | $0.50 – $1.00 / sq. ft. | $0.50 – $1.00 / sq. ft. | $0.50 – $1.00 / sq. ft. |

| Old Floor Removal (Tile) | $2.00 – $4.00 / sq. ft. | $2.00 – $4.00 / sq. ft. | $2.00 – $4.00 / sq. ft. |

| Subfloor Prep / Leveling | $0.50 – $1.00 / sq. ft. | $1.00 – $2.00 / sq. ft. | $1.00 – $3.00 / sq. ft. |

| Adhesives / Transitions / Baseboards | $0.50 / sq. ft. | $0.75 / sq. ft. | $1.00+ / sq. ft. |

| ESTIMATED TOTAL COST (w/o Tile) | $5.00 – $8.50 / sq. ft. | $7.75 – $12.25 / sq. ft. | $11.00 – $18.00+ / sq. ft. |

Data aggregated from local and national sources adjusted for the Florida market in 2025. Note: Tile removal significantly increases total cost.

6.3 Value Analysis

- Laminate: Generally offers a lower price entry point ($1.00 – $2.00 cheaper per sq. ft. in materials). However, once you add mandatory moisture barrier underlayment and potential upgrades for water resistance, the price gap narrows.

- LVP: Slightly higher upfront material cost, but often lower installation complexity (built-in underlayment).

- The “Repurchase” Factor: The true cost of flooring includes its lifespan. If an economy laminate floor swells due to moisture after 5 years and needs replacement, its “cost per year” is double that of a slightly more expensive LVP floor that lasts 15 years.

7: Design Trends and Aesthetics (2025 Outlook)

Functionality is paramount, but style seals the deal. Florida aesthetics are shifting in 2025, and both materials are adapting to meet this visual demand.

7.1 The “Death of Gray” and the Rise of “Blonde”

For years, “Cool Gray” was the dominant trend. In 2025, Florida design is warming up.

- Blonde & Honey Oak: “Coastal Grandmother” and “Organic Modern” trends favor light, warm, natural wood tones. These hide sand and dust better than dark floors and make smaller spaces feel airy and expansive.

- Greige: The transitional color. A blend of gray and beige (taupe) that offers the neutrality of gray but with the warmth needed to make a home inviting without looking sterile.

- Dark and Dramatic: A niche trend for luxury properties, utilizing deep Espresso or Walnut tones for a dramatic look, though it requires high maintenance regarding dust visibility.

7.2 Texture and Authenticity

- EIR (Embossed-in-Register): This is the game-changer for LVP. The texture on the surface perfectly matches the grain of the printed image. If you see a knot in the wood, you feel the knot with your finger. This technology has largely closed the visual gap between high-quality LVP and real wood, removing the “plastic” look of yesteryear.

- Wide Planks: The standard 5-inch plank is out. 7 and 9-inch wide planks are the standard for 2025. They create fewer seam lines and a more custom, expansive look, mimicking European hardwoods.

8: Resale Value and ROI

Does installing LVP or Laminate actually increase the value of a Florida home?

8.1 The ROI Hierarchy

Real estate data suggests a clear hierarchy in Return on Investment (ROI):

- Solid Hardwood: Still the “Gold Standard” for valuation (70-80% ROI), but risky in Florida due to maintenance and warping risk.

- Engineered Hardwood / High-End LVP: These are increasingly viewed as equals in the Florida market. High-end LVP is no longer seen as a “cheap vinyl” product, but as a desirable “performance” product for active families.

- Laminate: Generally has a lower ROI. It is seen as a budget renovation. While better than old carpet, it does not carry the premium prestige of LVP in coastal markets.

8.2 The Rental Property Perspective (Airbnb/VRBO)

For investors in Florida (especially near Disney or beaches), LVP is the undisputed champion.

- Durability: Withstands tenant abuse and “beach traffic.”

- Maintenance: Easy to clean between guests (turnover).

- Safety: Waterproofing protects the asset against negligent guests who leave wet towels on the floor or enter dripping wet from the pool.

- Laminate Risk: Installing laminate in a beach rental is widely considered a financial mistake due to the high probability of water damage within 1 to 2 seasons.

9: Deep Research Insights – The Verdict

Based on the synthesis of materials science, climate data, and market economics, we can draw nuanced conclusions for the Central Florida homeowner.

9.1 Why LVP Wins the “Battle of Humidity”

The molecular advantage of SPC (Stone Plastic Composite) over HDF (High-Density Fiberboard) is insurmountable in a tropical climate. While laminate technology has improved, it remains a wood-based product fighting against its own nature in a humid environment. LVP works with the environment—it is inert to moisture, stable in heat, and impervious to inevitable residential property water events. It offers the peace of mind that an AC leak won’t turn into a total floor renovation.

9.2 When Laminate Makes Sense

Laminate is not obsolete. It remains a viable contender for:

- Strict Budgets: If the primary goal is the lowest upfront cost for a dry area (e.g., a bedroom or home office away from plumbing), laminate offers excellent visual value.

- Extreme Scratch Resistance: For homes with large, active dogs where scratch resistance is the only priority (and humidity is controlled), highly-rated AC4 laminate is incredibly tough.

- Flippers: For those buying and selling homes quickly who need a fast cosmetic upgrade in dry living areas, laminate offers good visual “pop” for the price.

9.3 The Final Recommendation

For the vast majority of Florida homeowners—especially those looking to install continuous flooring throughout the entire home (including kitchens and bathrooms) to create visual flow—SPC Luxury Vinyl Plank is the superior choice. It offers the best balance of durability, moisture immunity, aesthetic versatility, and long-term value.

Frequently Asked Questions (SEO Optimized)

Q: Is “Waterproof” Laminate really safe for a Florida bathroom?

A: While marketed as waterproof, most laminates are only surface water-resistant for 24 to 72 hours. If a pipe leaks or moisture rises from the concrete slab (common in Florida), the wood-based core can still swell. For Florida bathrooms, LVP (which is 100% plastic/stone) is the safer, fully waterproof option.

Q: Does LVP fade in the Florida sun?

A: All flooring can fade with intense UV exposure. However, LVP with a high-quality UV-resistant wear layer performs well. In rooms with direct, intense sunlight (like sunrooms), we recommend using window treatments or choosing an SPC core LVP, which is more stable under heat than older vinyls.

Q: Do I need a vapor barrier under LVP on a concrete slab?

A: Yes. Even though LVP is waterproof, moisture rising from the slab can cause mold growth under the planks or affect the locking mechanism. Most quality LVP comes with an attached pad, but a 6-mil polyethylene vapor barrier (visqueen) is often recommended for ground-floor slabs in Florida as extra protection.

Q: Can I install LVP over my existing tile?

A: Yes, this is very common in Florida! As long as the existing tile is flat and grout lines are not too deep (or are filled), LVP can “float” directly over the top, saving the mess and cost of tile removal.

Q: Which flooring adds more resale value in Florida?

A: High-quality LVP is currently trending with higher resale value than laminate in Florida, specifically because buyers value the “waterproof” and “low maintenance” aspects in our humid climate. Solid wood floors have high value but scare some buyers due to upkeep.

Report Conclusion

The battle between LVP and Laminate in Florida is ultimately a battle against the elements. While laminate offers a strong, scratch-resistant surface, its wood-based heart leaves it vulnerable to the state’s pervasive humidity. LVP, particularly rigid core SPC, represents a material evolution designed to survive and thrive in the unique conditions of the Sunshine State. For the Central Florida homeowner looking to build confidence in their investment, choosing the material that respects the climate is the first step toward a lasting, beautiful home.